Food Safety Culture: What you need to know

to mee BRCGS standard Issue 9

Food Safety Culture: What you need to know

to meet BRCGS standard Issue 9

1. Introduction

For a food quality management system to be successful, a positive food safety culture among your company’s leadership and employees is a must.

Simply put: a good company with a consistently negative culture won’t last.

This is nothing new. Promoting food safety culture has been a feature of totrain’s own John Husband since first becoming a BRC training partner in 2002. But with the introduction of BRCGS Global Standard for Food Safety Issue 9, emphasis on culture is greater than ever. And a core part of totrain’s work in helping companies improve food safety culture via our tolearn food safety management platform (Book a demo)

So John sat down for a chat with Roy Anthony on Food Safety, The Facts to shed some light on the topic and what BRGCS expects.

Starting with an important question…

2. What’s the difference between food safety management systems and food safety cultures?

Imagine you’re building a brick wall.

“We take the first brick and on the front of it, we can write ‘cleaning schedules.’ We put that down, take the next brick and write ‘pest control’, and put that down. We take the next brick and write ‘vulnerability assessment.’

“Slowly, [we] build ourselves a wall that covers all the requirements of a food safety quality management system”.

“The problem is, if I then stand behind that wall, put two hands on it and push it, it’s going to fall over. Because there is no cement between the bricks. So what we need to do is put the cement between the bricks which for me is the food safety culture comprising of company values, beliefs and behaviours within the company”.

3. Food safety culture is the values, beliefs, attitudes and behaviours within an organisation

Every food company has a food safety culture. What BRCGS require is that you understand whether or not your culture is positive or negative.

“Once we understand that and where we are on the scale, we can start to improve food safety culture within the organisation.”

But let’s take a step back. What exactly is food safety culture?

John splits into two areas:

4. What defines food safety culture

“Values. And values are really important. Because values are what your company and you value, or think is important”.

“They’re also how you are judged by your company and work colleagues on the way you conduct yourself, and how you judge others.”

Here’s an example of how a value like positive work ethic might impact a work environment.

“One of the company’s value is employees should have a positive work ethic which has been documented within their policy and procedures and you as an employee have a positive work ethic”.

“But you may also have a group of work colleagues who have a negative work ethic. [Such as], they are lazy and only undertake jobs that are easy to do”.

“In this situation, their behaviour towards you may be aggressive, intimidating and bullying. Because you do not align with their own values”.

“We can now see how individuals or groups can influence others in the workplace. It’s therefore important we have a company employee who supports the company values”.

“I would [also] take it one stage further: those values [should be] clearly documented within policies and procedures and trained out on a regular basis.”

Besides values, food safety culture is defined by beliefs.

“These are ideas that people hold to be true. And your rights, even if irrational. Quite often these are developed from life experiences and work experiences.”

5. What demonstrates food safety culture

There are two key elements.

The first one is:

“People’s attitudes. Attitude is how you express your values and beliefs through verbal and written communication, and body language.”

The second one is an area BRCGS is particularly focused on:

“People’s behaviours. People’s behaviours is basically how you act or conduct yourself”.

“It’s important that companies define and document values and expected behaviours within their policies and procedures.”

Food safety culture can be driven by a mission statement—a simple, concise description of what the company do, why you exist and what purpose you serve.

Here’s Starbucks’ mission statement as an example:

Its mission is accomplished by its values, attitudes and behaviours:

- “Creating a culture of warmth and belonging, where everyone is welcome.”

- “Acting with courage, challenging the status quo and finding new ways to grow our company and each other.”

- “Being present, connecting with transparency, dignity and respect.”

- “Delivering the very best in all we do, holding ourselves accountable for results.”

To create your mission statement, focus on:

- What you offer

- Who you offer it to

- Why you’re doing it (i.e., your core values)

Combine these into a sentence or two that underlines your food safety culture.

6. What to improve in food safety culture? Understand your behaviours

BRCGS Global Standard for Food Safety Issue 9 puts more emphasis on changing behaviours.

A point raised in section 1.1.2 of the Global Food Safety Standard Issue 9 states that, to maintain and improve food safety culture, you need to understand the behaviours within your organisation. For more information click here to see Briefing note 1 – BRCGS global standard food safety issue 8 to 9.

John gives an example:

“Let’s say as an organisation, we have undertaken a food safety culture survey”.

“If and when you’ve reviewed the results of those surveys, one of the areas highlighted is the fact that operatives do not get enough time to actually clean down in between different production runs”.

“We could look at that and identify the behaviour. We could say that the behaviour revolves around the supervisor.

“The supervisor is being pressured to meet production targets [and] he’s behind on his targets. When it comes to cleaning in between different production runs, instead of giving operatives 30 minutes, he only gives them 20 minutes.

“What the Standard requires is that we need to sit down and explain to the supervisor that those behaviours are unacceptable. We then need to decide on an action plan going forward of how we may improve on that”.

“We should also detail some form of review to make sure that we’re achieving what we want to achieve”.

“However, we need to be careful. It’s very easy in this situation to blame the supervisor when, in reality, there may be a number of other things that could be causing the issue. The type of things I’m thinking of are where we’ve got a crowded production schedule, changes in production schedule, where we’ve got shortages of raw material, breakdown in equipment, operatives off sick etc”.

“So, as well as obviously changing the behaviour of the supervisor, we also need to look at the other situations that could be causing the problem.”

In other words, make sure you get to the bottom of a problem. If you know the root cause, you can effectively solve the behaviour. And improve your food safety culture.

7. The nitty gritty of BRCGS Global Standard for Food Safety Issue 9

BRCGS’ emphasis on food safety culture in Issue 9 starts from the top of the company.

As part of its statement of intent, BRCGS requires companies to have systems in place for the continual improvement of food safety culture.

The main area to focus on, though, is one we’ve already touched on: section 1.1.2. in the standard.

“[Section 1.1.2] starts by saying that organisations need a food safety culture plan. That food safety culture plan needs to clearly define the activities across the site that have an impact on food safety culture and the improvement of food safety culture.

“If a BSCGS auditor turns up at a site and you don’t have a food safety culture plan, they are required to raise a major nonconformity.”

Is a nonconformity as serious as it sounds? It can be.

BRCGS has three levels of nonconformity that impact your business in different ways.

“The first one is critical. And that’s where we’ve got a food safety issue. Or we have a breach of legislation”.

“If a company receives a critical, they either have their certificate removed/suspended or don’t receive a certificate”.

“With regards to major, it’s where we have a major breakdown in the system or something that potentially could lead to a food safety issue”.

“Minor is where we’ve got a minor issue. Examples could be a couple of documents not signed, people not wearing beard snoods [etc.].”

So, a food safety culture plan isn’t something to ignore.

Okay, back to the Standard. A big component in creating and maintaining a positive food safety culture can be found in the bullet points of section 1.1.2.

“The first one is communication. What this is trying to get over is: ‘How do we build in food safety communication on a daily basis?’

“What we mean by this is, if we’re having a production meeting at the beginning of the shift and [in] that production meeting, normally we’ll cover the production schedule for the day and what needs to be done. We need to also consider: ‘How do we cover food safety within that meeting?

“The type of things BRCGS is looking for is that we look at performance from the previous day. We identify good practice and bad practice with regards to food safety. And then we look at the production schedule for the coming day [and ask]: ‘Are there any issues there that we need to make people aware of?’”

To ensure good communication, John recommends creating a self-policing system. For example:

“If we’ve got a production line and some produce falls off the line. We’ve got a new employee who then picks it up and puts it back on the line. The operative stood with that employee [can] turn around and say: ‘I’m sorry, but we don’t do that. That’s not allowed.’

“What we’re doing is getting people within the system to self-police. We’re communicating the values and behaviours through our operatives. And we’re not waiting for managers and supervisors to pick up on things that aren’t being done correctly.

“For me, that is a great form of communication and demonstrates a very positive food safety culture.”

Good communication and, in turn, a positive food safety culture is rooted in training—educating and empowering employees to work effectively.

Typically, this involves telling people about legal requirements and what happens if they fail to comply. But BRCGS want you to approach training in a way that focuses on values and expected behaviours.

“I think a really good example of this would be something like induction training.

“We have a lot of companies in the UK employing people from all over the world. When they come into the factory, it’s important that we sit them down and make them aware of what is acceptable. ‘What are our values? And what are our accepted behaviours?’

“[In] companies that don’t have a robust induction system, people are passed on to other people. Then they tend to learn the bad habits from those people.

“So, training should be about making people aware of behaviours, as well as expected attitudes and values.

“[And] making people aware of the moral implication of why we need to produce food that’s fit for human consumption.”

8. Pay attention to performance measurement

Performance measurement is critical in improving your operations and food safety culture.

This involves things like analysing customer feedback and addressing complaints. And looking at micro results to make consistent progress.

But there are two other areas John says you need to think about:

- Results from internal audits

- Results from Good Manufacturing Practice (GMP) audits

“What we’re looking for is trends. As an example: if we carry out a fabrication and hygiene inspection and every time we do the inspection we find that the bins in that area are overflowing—that would indicate that we’ve got a cultural issue. Therefore, if we’re looking for things to improve, that may be one of the areas.

“I would suggest that all organisations need to be looking at the results of internal audits or GMP inspections to identify trends that could be an indication of a cultural issue.”

To change these cultural issues, your food safety culture plan should include action plans.

“Action plans need to clearly identify what behaviours we’re going to be changing, who’s responsible and timescales.”

To maintain a positive food safety culture, review plans periodically. The minimum requirement is annually, but you might choose to review plans more often.

9. BRCGS Auditors expect to see your food safety culture plans

When you get a BRCGS audit, the auditor is required to spend time with senior management reviewing your food safety culture plan.

This can be a Chief Executive, Managing Director, Production Director, Operations Director or HR Director.

It should not be a Technical Director, line manager, or supervisor.

“The auditor should sit down with that senior manager and go through their food safety culture plan. [Asking]: ‘What have they done in the previous year and what have they got planned going forward?’”

10. The indicators of a positive food safety culture

Clearly defined values and behaviours, with employees who understand and are confident in self-policing them, will help you maintain a positive food safety culture.

John also has other recommendations.

“I believe there should be some clearly defined feedback mechanisms and that people are encouraged to use them.

“Within the Standard, we’ve got a clause that requires a confidentiality system where people can report incidents. We also have the requirement that there needs to be systems in place for employees to be able to report out of specification. But I think having an open-door policy is very positive.”

Hazard awareness is also important.

“When we’re running HAACP training and BRCGS training, it’s quite worrying how many delegatese on the courses aren’t familiar with the actual hazards within their own processes.

“I would say [have] a really good understanding of the hazards within the actual process.

“You’re never too busy for food safety.”

11. Ready to build your food safety culture plan?

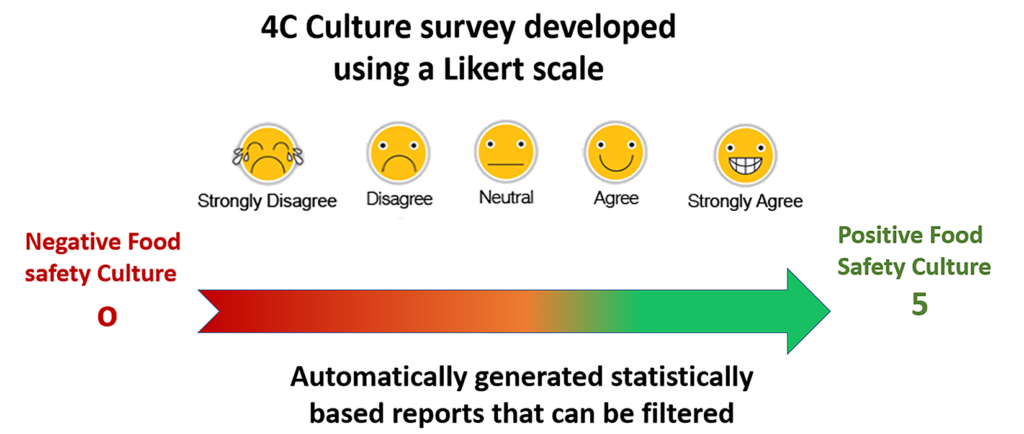

Our food safety management system tolearn helps you manage food safety training and run FSC questionnaires all from the same food safety management platform, ensuring that your employees have the knowledge and confidence to maintain a positive culture at all times.

To book a tolearn Food Safety Management Platform live demo at a date and time which is best for you to see how tolearn can assist your company with onboarding of staff, employee competency and improve FSC click on the button below.